Grid Gasketing

Grid Gasketing

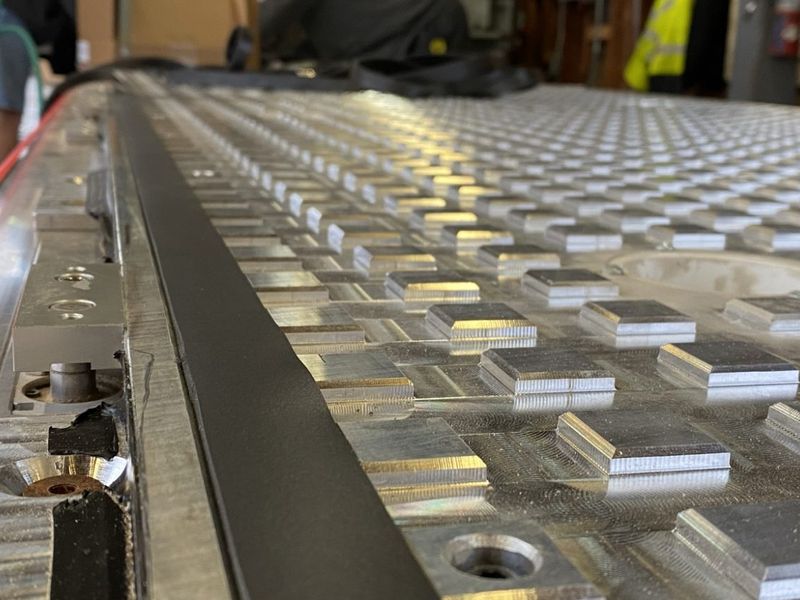

Grid Gasketing is the non-adhesive material used in the perimeter of the CNC Router table/pod itself. Depending on the type of router that is being used, both square and rounded products are available. The goal is to fill the channel width-wise and stand proud above the table roughly 1/16 of an inch. This will create an air-tight seal under your spoil board/fixture board.

Every CNC Router that is employing vacuum hold-down methods needs to incorporate some type of gasketing material. Most operators are familiar with the gasketing material that is placed in the outer most channel of their CNC router table. Many CNC Router training seminars will mention: “make sure to get some gasketing material to get good seal around your spoilboards”. This gasketing material is essential to fill the void between the router table and the spoilboard, creating a quality vacuum clamp on the spoilboards. We call this material Grid Gasketing and getting the proper material for your machine is the first step. This is the “foundation of the house” so-to-speak.

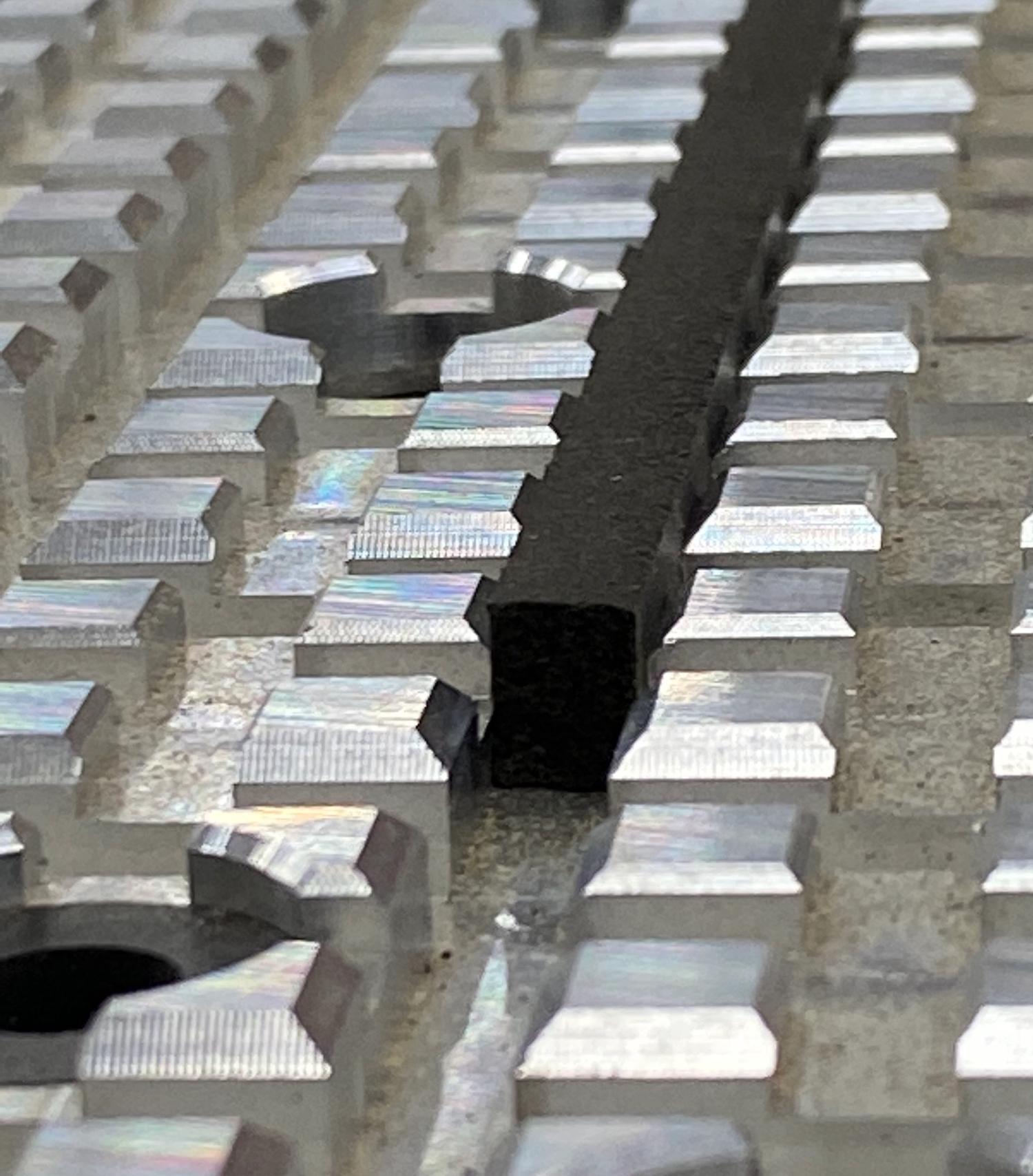

The ideal product will fill the channel width-wise evenly and stick above the surface of the channel by roughly 1/16”. We also feel as though a rounded channel should be fitted with a round gasket. Squared channels should be fitted with squared gasketing products. All Star CNC has a Grid Gasket product for each CNC Router Manufacturer. The proper Grid Gasketing product for a particular channel size is crucial to maximizing vacuum performance. Too narrow and it will slip in the channel. Too wide and it will pinch when trying to zero out on the z-depth.

Different router manufacturers mill their channels at different dimensions. On top of that, we feel some router manufactures will either provide or recommend a particular size gasket for their own machine, but we find that those products may not be the ideal gasketing product to MAXIMIZE vacuum performance. First thing we always do when talking to a new customer is to ask them what type of router they have. This will help to get an idea of the best gasketing product to provide. But the list we have developed is only a guide. When looking for the best grid gasketing product for your machine, follow these guides:

- Square channels use square gasket products. Rounded channels and dove-tail channels use rounded gasket products.

- The gasketing should stick proud above the table by 1/16″.

- Non-adhesive material is best. What it comes time to replace the gasketing there is not adhesive residue left behind in the channels.

- Replace the gasketing in your table like you would replace the oil in your car. For best results, this gasketing is creating a proper “base”. If the gasketing wears and becomes flush with the table, it is time to replace it. A flush gasket is performing as well as no gasket.

- The UMG 25 312 is the most commonly ordered product. It is ideas for the 1/4″ x 1/4″ channel that is so common in today’s routers.

Gallery

![]()

- Intended for use with any CNC Router that utilizes vacuum to hold parts

- Gasketing to seal under the spoilboard

- Tables with zones need gasketing for each zone

- One size/product does not fit all

- All Star Grid Gasket cut specific to ea. router mfg. table for perfect fit

- Specially engineered material components for longest life and performance

![]()

The proper size and shape Grid Gasket is essential to getting maximum vacuum. We always recommend replacing the round gasket cord with our custom-cut square products. This ensures an air-tight seal on your CNC Vacuum Table, under

the spoilboard and/or fixture board. This is the foundation for every CNC Router table vacuum system.![]()

How to utilize Grid Gasket

All Star Grid Gasket should be installed in the outer-most perimeter channels of your CNC Vacuum table. If your table has the ability to zone-off areas of the

table, each of those zones will need to be individually gasketed. Although All Star’s Grid Gaskets provide the longest life, all gaskets wear over time. Always

check and replace your Grid Gaskets frequently as part of your regular maintenance.![]()

What All Star Grid Gasket product is best for me?

The correct sizing, shape, and material are fundamental for proper vacuum performance. Every All Star Grid Gasket product is specially designed,

engineered, and manufactured for optimal fitment down to .002”. Our experts can help you select the exact product, specific to your router manufacturer, and guide you to a perfect seal. Knowing the accurate width and depth of your

table’s channels is essential.