Products

Grid Gasketing

![]()

Grid Gasketing is the non-adhesive material used in the perimeter of the CNC Router table/pod itself. Depending on the type of router that is being used, both square and rounded products are available. The goal is to fill the channel width-wise and stand proud above the table roughly 1/16 of an inch. This will create an air-tight seal under your spoil board/fixture board.

In Board Gasketing

![]()

In-Board Gasketing products are for creating dedicated fixtures for dedicated long-term parts. The benefits gained from utilizing a proper dedicated fixture are enormous. Placed in the pre-routed channels of a non-porous fixture board, these tools maximize vacuum performance, with accurate z-depth tolerances, extended tooling life, and more. If you are doing repetitive parts, do it with In-Board Gasketing.

On Board Gasketing

![]()

On Board Gasketing is an adhesive-backed material that is placed directly on the surface of a fixture or spoil board. It creates excellent holding power when doing short-run jobs and a dedicated fixture is not desired. The vacuum that is centralized and concentrated to a part like this is not possible without a gasket solution.

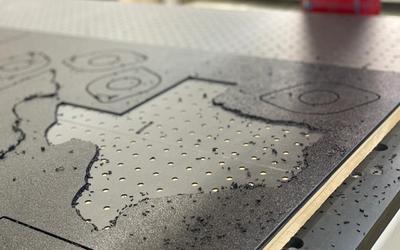

Tile Gasket™

![]()

Our Patent pending Tile Gasket™ products were created for our Nested Base Manufacturing customers. For those looking for the benefits of a proper gasketing solution, but jobs that are constantly changing, these tiles offer the best solution. By covering an entire MDF porous spoil board with these non-porous tiles, not only is the vacuum less likely to leak from tool paths that are being cut, but the sum of 1/4″ holes creates a universal clamping system that holds entire sheets more effectively.

Vacuum Clamping Gasket Kits

![]()

Our All Star Vacuum Clamping gasket kits come with everything you'll need to have your vacuum table holding parts stronger than ever. Each kit includes two bags of Grid Gasket precision cut specific to your table's channel dimensions ensuring an air-tight fit when sealing to your spoilboard. Also included is our patented Tile Gasket - a real game changer for holding parts on top of your works surface. Utilizing the physics behind vacuum clamping, Tile Gasket is far more powerful and efficient in holding firm even the smallest parts when compared to down-drafting on an open MDF spoilboard. Click here to see how the principle of Vacuum Clamping work. When you receive your kit, not only will you get gasket for clamping, but also application notes, handy magnetic conversion charts, and other fun swag and support.

Shop Sabre Vacuum System Upgrade Kit

![]()

Turn your Shop Sabre CNC Router vacuum system into an All Star superstar with parts holding power. This kit includes Grid Gasket to sit in the vacuum plenum and seal up to your spoilboard greatly reducing leak. Testing shows that by simply adding this gasket you can double your parts holding. Watch the video showing the improvement here. And since Shop Sabres have a unique trapezoidal channel, we've included special double-sided tape to help hold the round cord in place. From there we focus on holding parts on top of the spoilboard using our Tile Gasket for a real game-changer in firmly holding your parts. Enough tile Gasket is included to cover your whole table, along with supporting application notes, magnetic conversion charts, and other helpful and fun swag.